Détecteur de défauts Ultrasons par MAUT DOLPHICAM 2

Ultrasonic testing re-imagined, use an "ultrasonic camera" see a live image at 20-100 frames per second. The Dolphicam is flexible, adaptable and intuitive; made with expanded capability in mind and designed to be learned quickly by experts and non-experts alike.

With an inspection depth of up to 60mm it can be utilized to inspect metals, multi-materials, carbon and glass fibre reinforced polymers as well as glass laminate aluminium reinforced epoxy. Utilizing unique 2D matrix transducer technology the Dolphicam enables a wide variety of transducer frequencies and custom transducer design. If you add extreme data signal processing capacity as well as a smooth user experience to that, you have the ultimate NDT tool.

Features

- Real-time images.

- Frequency range from 0.5 to 15 MHz.

- 128 x 128 transducers electrodes.

- 16384 transducer elements.

- Size 3,8 x 3,8 cm.

- 2D and 3D images.

- A-, B-, and C-scans.

- Amplitude & Time of flight.

The Platform

The Dolphicam is a tool for experts and non-experts doing non-destructive testing. Dolphicam2 has unique signal processing which is visualized with great user experience.

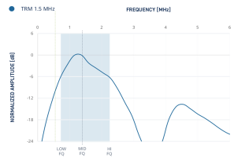

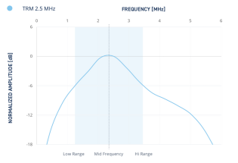

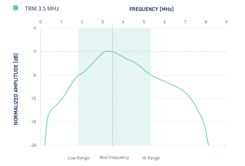

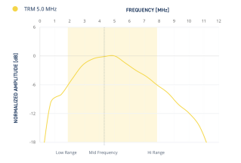

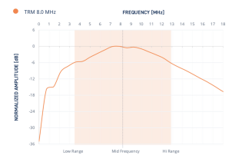

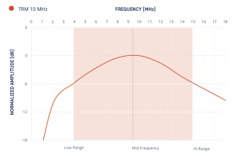

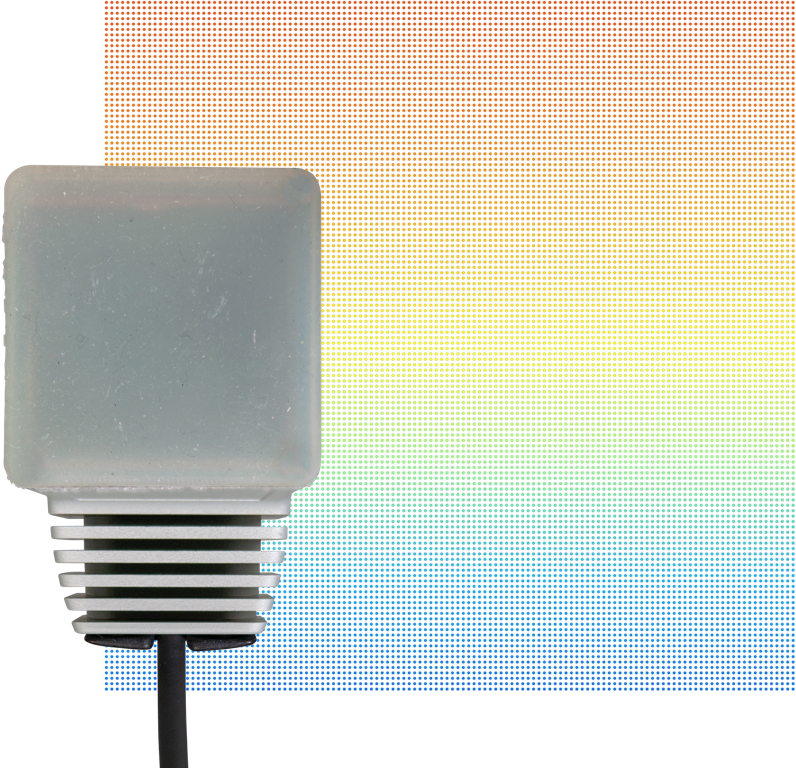

Unique Combination of Frequencies and Couplings

The combinations of different TRMs and couplings of varying softness/hardness and sizes enable many possibilities of inspecting multiple types of materials.

Scans

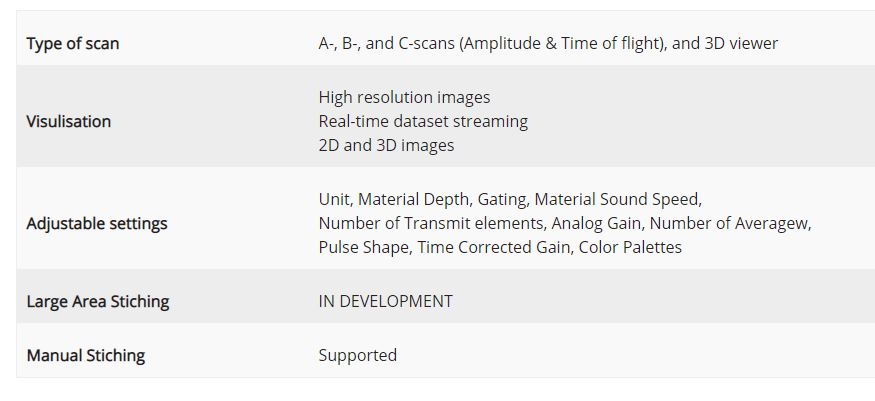

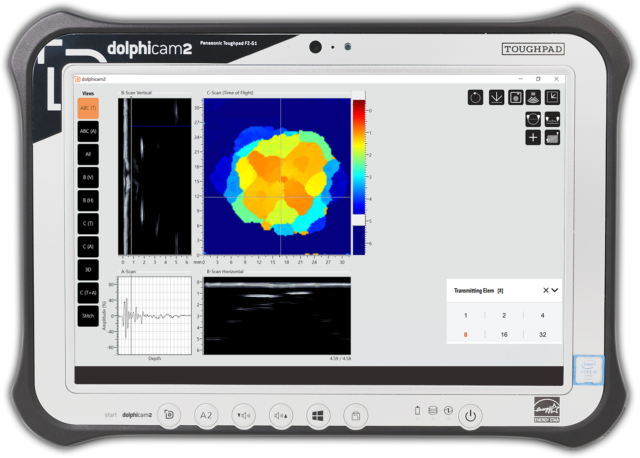

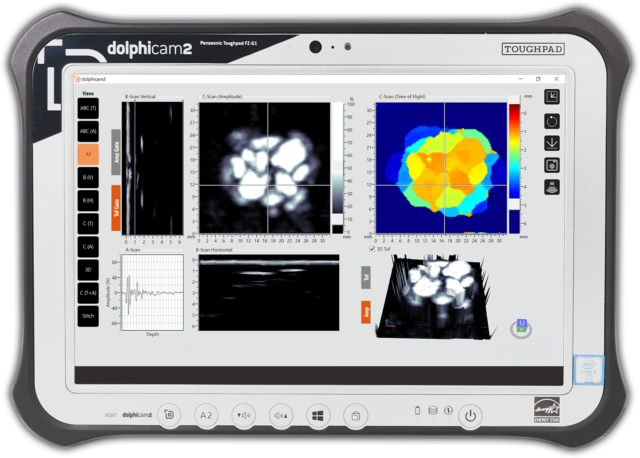

The Dolphicam2 Software has a user friendly dashboard with highly customizable and configurable settings.

- Real time images.

- 2D and 3D images.

- A-, B-, and C-scans.

- Amplitude & Time of flight.

- Large area stitching.

- “Traffic light” color palettes

Configurable Settings

- Unit, material depth, number of Amp Gates, number of ToF

- Gates, Material Sound Speed, Transmitting Elements, Analog

- Gain, Number of Averages, Transmitting Pulse Shape, Time

- Corrected Gain, Time of Flight Palette, Amplitude/B-scan

- Custom Palettes

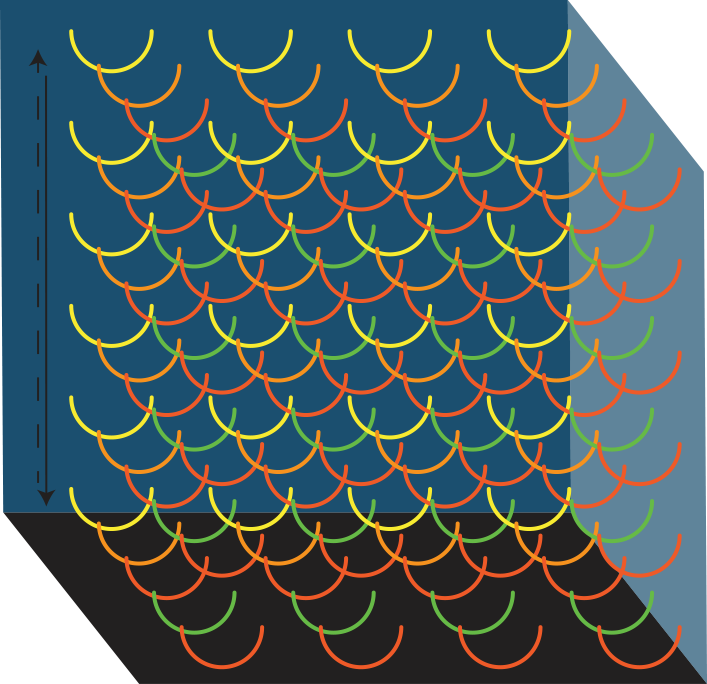

Dolphitech Matrix Transducers VS Phased Array

Dolphitech Matrix transducers have transducer elements in a 2-dimensional array. Since the transducer directly covers the area of inspection, no encoder system is needed to calculate the position of each element. Minimising the risk of positional errors due to faults or imprecision in the encoder system.

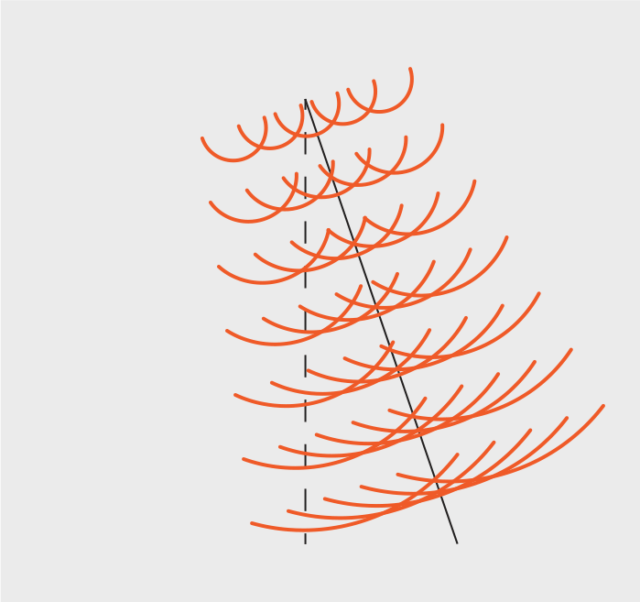

Phased array transducers contain a number of individual transducers that can be pulsed individually to steer and focus the sound beam in a specific direction. Linear arrays are usually used in combination with an encoder system matching the signal with positional information to build a 2-dimensional image.

Substantial improvements in resolution are to be expected from a Dolphicam Ultrasound camera system compared to an Olympus MX phased array system.

MATRIX TRANSDUCERS PHASED ARRAY

More Data Than Enough Data

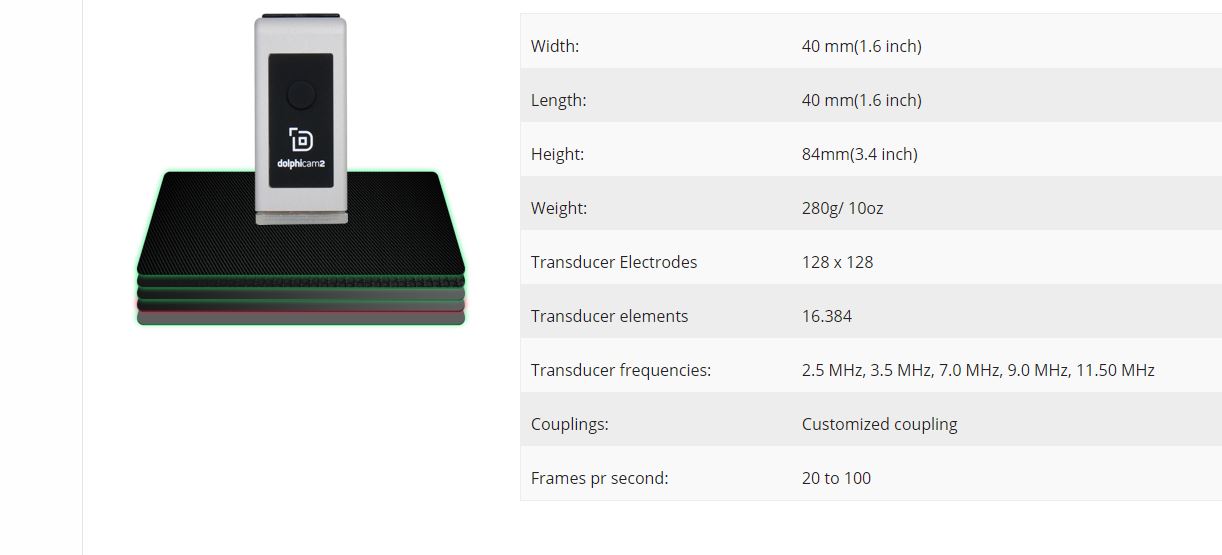

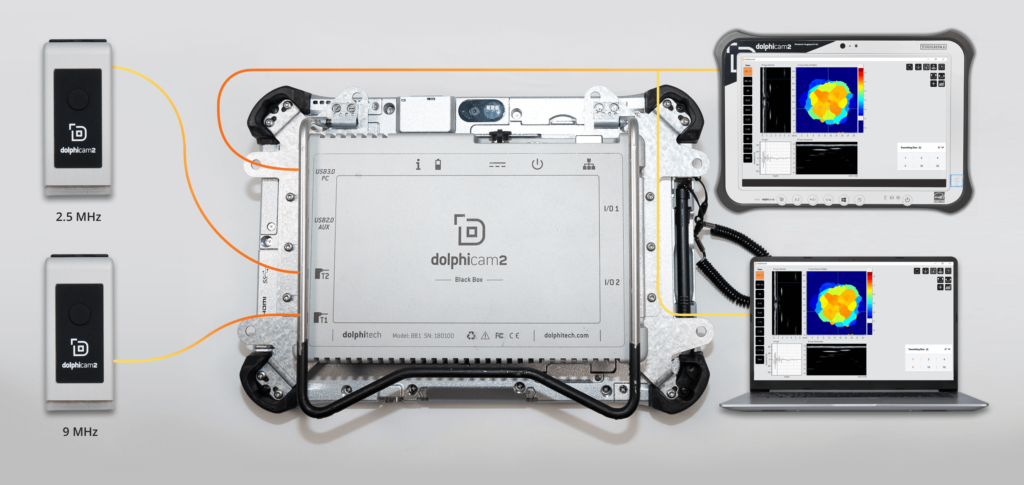

The TRM has 128 horizontal and 128 vertical transducer electrodes. This makes a transducer element where one horizontal line crosses a vertical line. I total 16.384 transducer elements send and receive sound to create the data with a frame rate from 10 to 100 frames per second.

In short, scans deliver more data than we can use for now. For you, this means that the product you buy today only will get better tomorrow.

Ultrasound

Turn on the device and start scanning (1 min from start to ready to scan). For a user you will spend less time calibrating and more time fixing.

The «Traffic lights» pallet or real-time dataset streaming visualizes the scan in a way that impresses experts, and lets non-experts understand what they see.

Large amounts of Data is being processed to a user-friendly dashboard.

Small, Flexible and Mobile

Its size and weight makes it easy to hold, and access places that are really difficult to scan. The TRM is made small, ergonomic and fits nicely in your hand.

Stitching

Dolphicam comes with multiple different stitching solutions, from manual grid tool to fully automated systems. Depending on your needs for accuracy and speed, the Dolphicam can offer different ways for scanning large areas and combining into one image.

FTD - Flexible Transducer Development

Transducer technology is very flexible, allowing for customizable design for customers with specific needs.

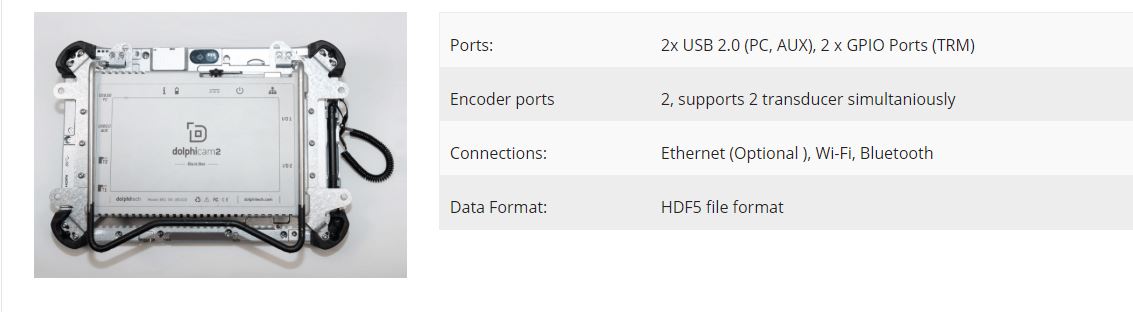

Specifications

COUPLINGS

TRANSDUCER MODULE

SOFTWARE

BLACK BOX